WELCOME to our blog

Where we write about the fascinating world of manufacturing, prototyping and engineering. We cover a wide range of topics we hope you find as interesting as we do.

Low Volume Injection Molding

With the power of injection molding, there is one trade of: tooling is expensive and complex. The cheapest mass run CNC machined molds start around $10k and can balloon from there. Add in small detail features or multiple injection points and the tools can become huge investments.

What is LEAN Manufacturing

In the world of manufacturing, one of the most spoken words is “Lean.” Some talk about lean methodologies, others talk about lean processes. They all are looking for the same idea, which is to say, remove waste from the system.

OxyAcetylene Cutting and Welding

Oxyacetylene welding still has a place in our modern world. Its flexibility and unique characteristics earn a pair of tanks a spot in any metal shop. It is also critical to understand, it is not always the best for every job.

Anodizing

Anodizing is a pretty amazing process. It brings with it so many advantages, all with such a small cost, allowing a designer to take full advantage of the aluminum benefits.

The history of 3D printing

Sometime in the mid-2010s, additive manufacturing, or 3D printing, became the hottest buzzword amongst engineers. Before then, it almost seemed like science fiction, where only the most advanced schools had printers to help in research. This host of technologies has taken over engineering since then and is now a required skill for an estimated 35% of open engineering job postings. So, when did 3D printing actually start? What did these early attempts even look like?

What the heck is Kaizen?

Kaizen is a Japanese word meaning “good change.” This word has become synonymous with process improvement and streamlining. As one of the main tenants of the Toyota Production System (TPS), most manufacturers seek to utilize Kaizen. The core idea is to find and make positive changes continuously. Different companies implement this idea in different practices, but the core philosophy remains the same: never stop improving your processes.

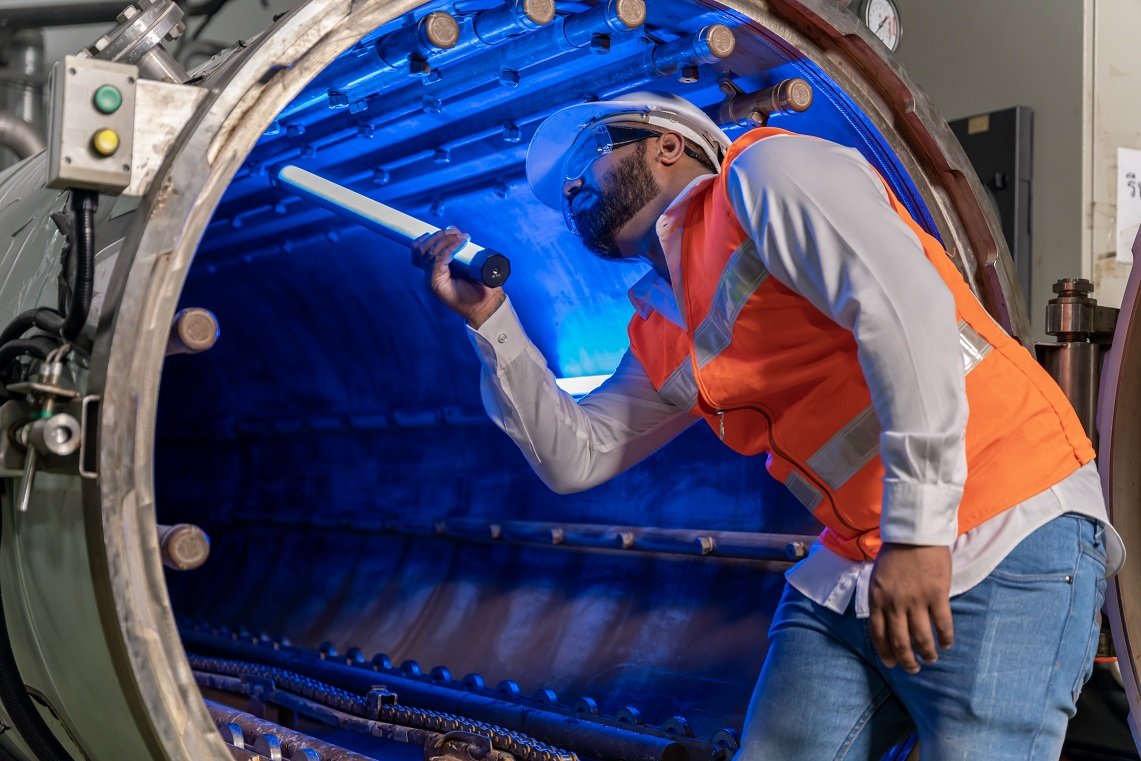

What is NDT

Non-Destructive Testing covers the inspection of material, usually while searching for cracks or other defects like porosity. The goal is to determine if a manufacturing process (or usage of the part) has caused undue stress which might lead to failures. Most commonly used on metallic parts, some of these techniques can even work on plastics or ceramics.

The Six Sigmas

For our sixth blog post, we’re going to discuss Six Sigma, which implies a slew of methodologies and tools. We are going to focus on those here and how they can have a positive impact on your manufacturing environment.

Succeeding in small scale production

The term “job shop” always seems to carry a negative connotation. I don’t think that’s fair, and today we’re going to look at some ways to make a small shop succeed beyond their large competitors imagination.

Fillets, Chamfers, Edge Breaks Oh My

Without them, parts would be out of dimension during manufacturing, cracking would become more prevalent, and handling them would be a bloody mess. Conversely, with too many; parts won’t mate correctly, fastener heads would have diminished contact area and manufacturing costs would be through the roof.

Selecting Drawing Specifications

We are looking at the critical step of selecting and preparing drawings based on specifications. Let MFG Concepts guide you through the selection, leading to long term affordable manufacturing.

Manufacturing inflatables Case Study

In this blog post we uncover the secret manufacturing processes used to produce everyone's favorite new Christmas decorating trend.

Starting MFG Concepts

We started MFG Concepts to produce prototypes at an affordable price. Too many great ideas are shot down by lack of resources and specific knowledge.